Soilmec provides the foundation engineering and underground construction industry with a full spectrum of innovative equipment solutions. Soilmec’s product line has the most advanced, powerful, versatile, and safest rigs in the world. Their products are supported by the best in hands-on customer service and operator training.

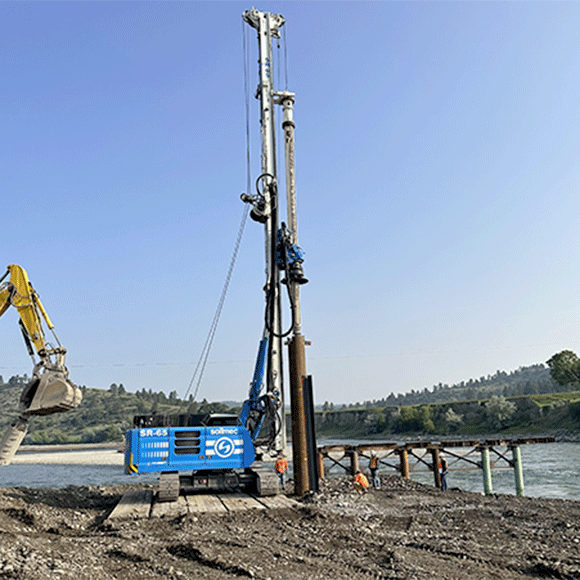

Soilmec Foundation Drilling Rigs

Soilmec is an international, Italian leader as a construction equipment manufacturer, primarily focusing on the production and manufacturing of drilling machinery used in the foundation drilling industry.

Additional Drilling Rig Information

In recent years, Soilmec has expanded their machine product lines to include those in the crawler cranes and tunnel boring machines categories. Soilmec offers the unique service of analyzing and archiving a machine’s on-site behaviors to be studied by their team of engineers. This enables them to create design solutions for issues directly experienced by Soilmec customers on real job sites.

The wide variety of models allows the performance of any pile foundation, micropiles, diaphragm walls, and more. Soilmec makes it a point to include in-field experience as a vital part of their model’s designs and use philosophies, as well as safety and innovation.

As end-to-end problem solvers, Soilmec’s machinery proves pivotal on any job site and you could be looking for any of these machines as a Soilmec for sale:

- Large Diameter Piling

- Continuous Flight Auger

- Micropiling

- Cranes

- Hydromill

- Ancillary

Product Lines

Large Diameter Piling

Soilmec offers the best and newest large diameter piling rigs with their SR line. Their large cabs increase visibility and comfort, while the DMS technology provides superior operator control.

Ancillary

Need grout pumps, buckets, coring barrels, rock augers, under-reamers, or other ancillary equipment for your rig? Soilmec has it all.

Hydromill

Typically attached to a crawler crane and used in the casting of slurry walls, Soilmec’s hydromill trench cutters offer superior soil-crushing power.

Cranes

Soilmec’s heavy-duty cranes are self-assembling, versatile, and easily transportable. These machines have many applications beyond general lifting including: hydromill, hydraulic/cable grab, hammer grab, hydraulic vibrator, hydraulic/mechanical rotary, and pile driving.

Continuous Flight Auger

Soilmec rigs offer configurations for continuous flight auger cast piling. This technology creates a continuous pile by first excavating a hole and while the auger is extracted, concrete is injected through a hollow shaft into the hole.

Micropiling

Soilmec’s micropiling line was designed with efficiency, productivity, and safety in mind. Most micropiling rigs can be configured using single or double rotaries, top-hammer, or vibro-rotary for consolidation, micropiling, and anchoring.

We’ll Help You Find the Right Equipment

Wether you’re looking for a technical information, a job-specific equipment consult, or just a brochure, submit a request and we’ll get back at you within a day – at no cost to you. Soilmec machinery and equipment is used every single day on job sites found around the world, speaking to the reliability, innovativeness, and design of this company’s equipment.

Drilling Deeper

Large Diameter Piles

(LDP) Large Diameter Piles performed with adaptive kelly bar and penetrating device (Augers, Drilling Buckets, and Core Barrels) is the most normally utilized innovation all through the world, as it permits to bore piles in a dirt or rock. Exhausted heap is a cast set up substantial heap where the exhausted piles must be projected on place of work.

Benefits:

- Adaptive kelly bar permits to perform extremely profound piles.

- Broad scope of drill devices, housings and other assistant gear fit to drill in dirt or rock.

- Length and diameter can be promptly differed to suit changing ground conditions.

- Large unearthings and ensuing refill are killed.

- Non appearance of vibration won’t upset nearby piles or designs.

- Offer higher limits with possibly preferred financial aspects over driven piles.

- The large diameter exhausted piles are frequently applied in the execution of underpinnings of piles for extensions and viaducts in the water.

Continuous Flight Auger

CFA (Continuous Flight Auger) innovation joins the upsides of fixed heaps with the adaptability of use of penetrated heaps. Continuous Flight Auger heaps are performed with a fractional soil evacuation, in this way with a parallel soil pressure that expands the last burden bearing limit. The development technique consists of exhausting the dirt through a continuous flight auger collected on a focal empty line. On consummation of exhausting activity, auger is removed while concrete is poured all through the inward empty line. When required, heaps might be supported for their whole length with support confines embedded in the still wet cement.

Benefits:

- The innovation doesn’t deliver shocks, vibrations, commotion, permitting to work in metropolitan regions.

- The base required gear permits to limit the place of work establishment plant and to work in exceptionally confined regions.

- High modern creation rates can be handily reached.

- The technique can be used in a wide scope of firm and cohesionless soils, regardless of the presence of a water-bearing layer and without bentonite liquid as divider support.

Micropiling

There is a large field for the application of micropiles. Also known as mini piles, micropiles are constructed using high-strength, small diameter steel casing and/or threaded bars and then grouted into position. Micropile drill rigs are extremely versatile and can venture outside of the traditional job site conditions. Rod and casing installation can be successfully drilled in restricted access, low headroom sites, and at a various degree of angles and ground conditions. Additional small diameter piles can be added to existing foundations for further stabilization.

Benefits:

- Jet grouting

- Tie Backs

- Soil Nailing

- Enhance ground stability

- Load transfer

- Providing structural support

FINANCING NOW AVAILABLE

We now offer leasing, loans, equipment refinancing, residual leases, seasonal leases, seasonal payment options, repairs financing, and more! Financing available with tooling on rig purchases.